CLT Research

When designing for the future, it is important to recognize that two of the world’s most widely used building materials are also among the most environmentally intensive. Together, steel and concrete account for about 16% of annual global carbon emissions. Despite this, over 1.86 billion tons of steel and 10 billion tons of concrete are produced each year.

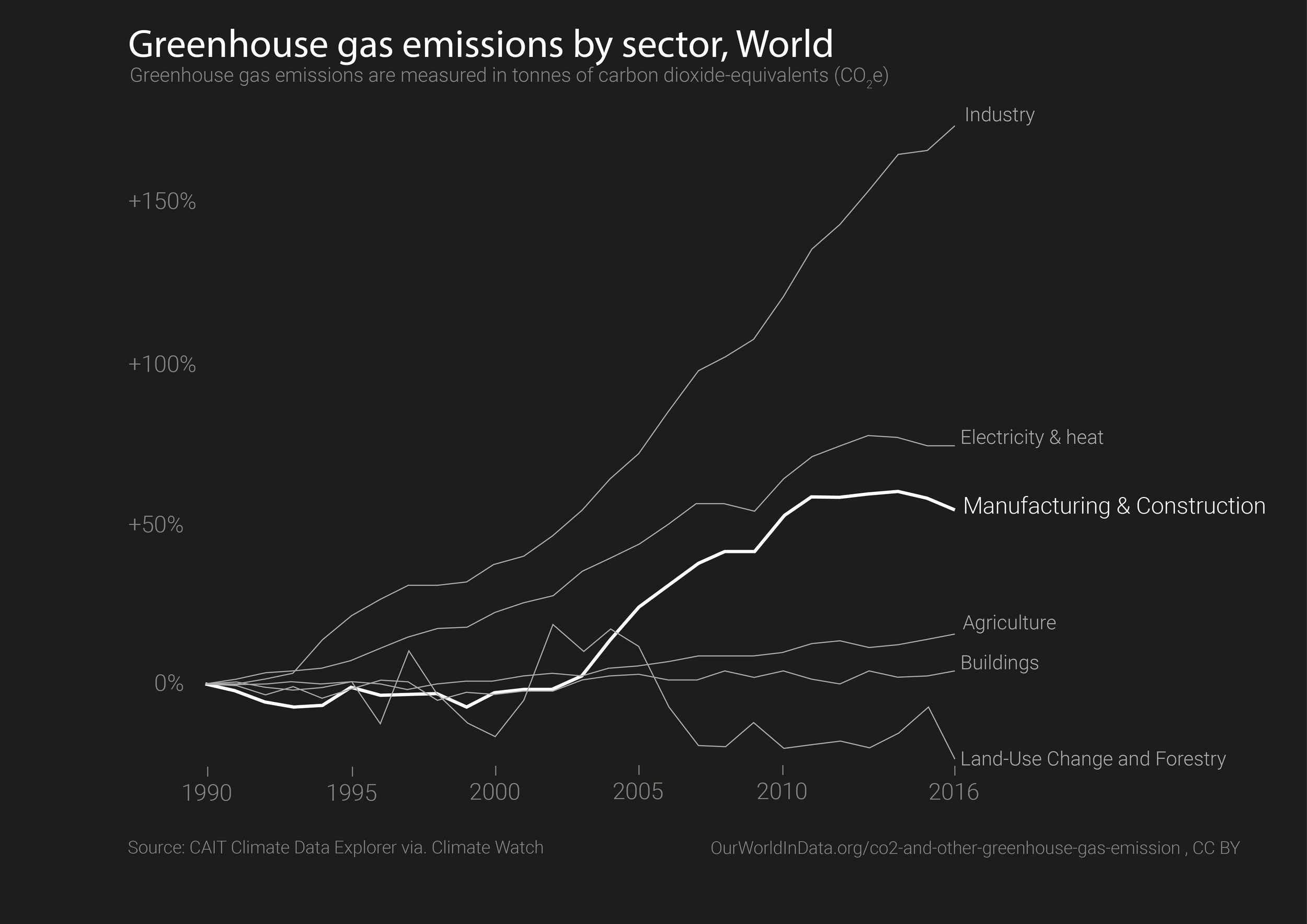

Until recently, there were no viable alternatives, as the two materials were widely available, affordable, and structurally versatile. They are the building blocks of our world. But as the environmental crisis intensifies and global carbon emissions continue to rise to unprecedented levels, new approaches to construction are emerging — offering the promise of a lower-impact, climate-conscious future.

Cross-laminated timber (CLT), an engineered product made by gluing sheets of wood together crosswise, is gaining popularity. Unlike other engineered woods, CLT has two-directional spanning capacity, meaning it can replace concrete slabs for floors, walls, and roofs. This makes it possible to design buildings from houses to skyscrapers with completely timber structures. Significantly, the material can reduce a building’s carbon footprint by 80% compared to using concrete.

Due to CLT’s great potential, we at de baes architects have been researching and implementing new ways of using the material to create high-functioning and aesthetically distinguished buildings. First and foremost, life-cycle analyses demonstrate that CLT can be a carbon-negative material. Beyond that, it is aesthetically pleasing and creates warm, inviting environments.

ICU New Physical Education Center by Kengo Kuma & Associates

Along with other engineered woods, CLT is structurally versatile. It can be used for cantilevers, long-span spaces, and curving organic forms. Also, since CLT elements are prefabricated, the material lends itself to modular buildings and allows for fast construction times. Brock Commons, an 18-story tower at the University of British Columbia, was erected in only eight weeks.

CLT is also fully recyclable. A CLT-building that has outlived its functional life-span can be dismantled and the wood can be reused. Since it is lightweight, CLT is an excellent choice for extensions to existing buildings as it avoids the need for costly reinforcement. Also, because CLT chars when exposed to flames, it is naturally fire-resistant.

Audrey Irmas Pavilion by OMA

Of course, designing with CLT comes with its own considerations critical to a project’s success. It is not as inherently soundproof as concrete. Therefore, we often use CLT with hempcrete, gravel, and acoustical treatments. Since CLT creates thick solid floor slabs—and we often want to expose the wood—mechanical systems can not be hidden in CLT buildings like in concrete and steel ones. CLT slabs are also produced offsite and need carefully planned penetrations to ensure structural stability.

As architects experienced with CLT, we understand its advantages and unique considerations. For example, we are currently working on Marshland House, a prototype for a CLT residence designed to adapt over time. It features columns that provide flexibility to partition the home and reconfigure it over time. Similarly, we are designing a multi-functional pavilion for Nieuwe Voorhaven that showcases the versatility and design potential of CLT.